The Submerged Arc Welded Steel pipe Production Line is the core equipment for manufacturing high-strength steel pipes, mainly used in oil and gas transportation, building structures, and other fields. Its core processes include straight seam submerged arc welding (JCOE/UOE) and spiral submerged arc welding, ensuring the strength and precision of the steel pipes through precise forming and welding technologies.

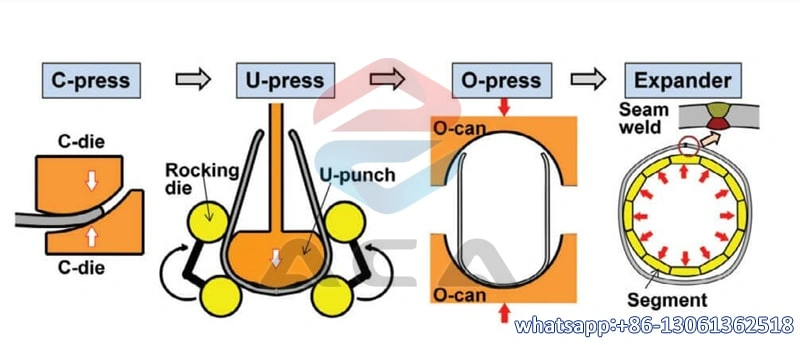

Our ACA company's straight seam submerged arc welding (JCOE/UOE) steel pipe production line uses a mandrel rotating continuous forming method, equipped with a steel plate pre-bending machine, steel plate forming press, seam welding machine, and internal and external welding equipment. It can produce steel pipes with diameters of Φ406-Φ1829mm, Pipe wall thicknesses:6.0-80mm.

Our Pipe machinery make the the steel pipe products which have low residual stress and no surface scratches. The Pipelines comply with international standards such as API and BS.

Most large pipelines for oil and gas transportation use JCOE production lines to produce large-diameter steel pipes, and advertising signposts and drinking water pipelines also utilize submerged arc welding steel pipe technology.

Our company's JCOE steel pipe production line also has further the following main technical characteristics:

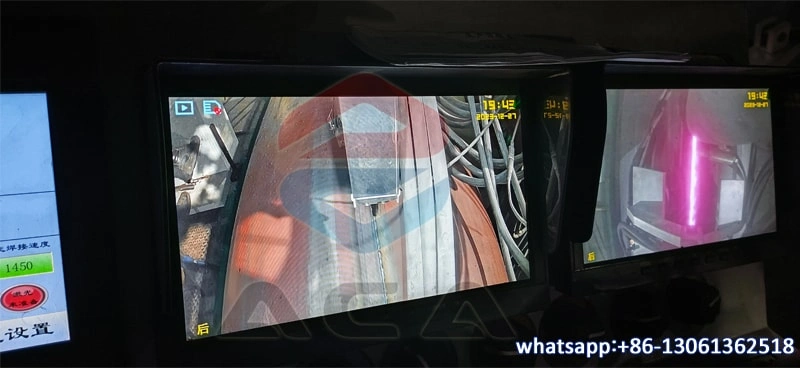

1. High degree of automation: Uses digital twin technology to achieve automated centralized control.

2. High-precision detection: Equipped with ultrasonic flaw detection, hydraulic testing machines, and other equipment to ensure the quality of finished steel pipes.

Related Video: